For CNC/ Milling/ Grinding Machine Permanent Magnetic Chuck

Magnetic Chuck

Features:

1. Strong suction cup panel, good stability,not distortion during

process, which can realize percision processing

2. Simple mechanical switch , “off” and "on"

3. The magnetic force produced by high energy materials,no time

limit,no energy consumption ,no heat, environmental safety

4. Simple quickly replacement of the clamping workpiece, shorten

clamping adjust time, improve work efficiency

1. High powered magnets are used for making standard pole permanent

magnetic chucks.

2. The magnetic and non magnetic stainless steel are furnace

brazed, making a solid, one piece construction.

3. The magnets can be drilled to a required depth. It is between

the poles or anywhere in the top that drilling or machining is

done.

4. At the top plates there are no magnets. Handles on all permanent

magnetic chucks are removable.

Features:

Powerful permanent magnetic chuck table for grinding machine can be

used for processing various magnetic workpieces, especially for

powerful milling and grinding working.

The main uses and characteristics

1. Fine frinding on six faces. Applies to surface grinder, EDM

machine and linear cutting machine.

2. Pole space is fine, Magnetic force is distributed uniformly. It

performs well on thin and tiny workpiece machining. The working

table precision doesn't change during magnetizing or demagnetizing.

3. The panel through special processing, with no leakage, prevents

corrosion by cutting fluid, extends working life and enables to

work longer time in cutting fluid.

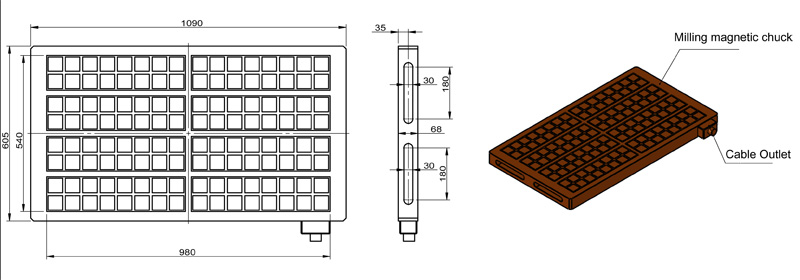

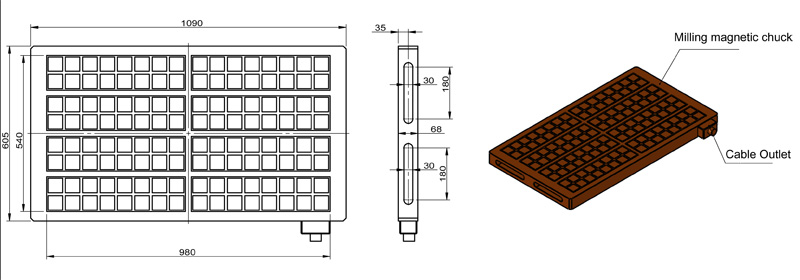

Permanet Magnetic Chuck Drawing

What is electro permanent magnetic chuck?

Electro permanent magnetic table is widely used in lathe, milling

machine, boring machine, grinding machine,Mobile phone chuck,

turnout processing etc., using the overall processing, the inside

without moving parts, with high strength and high rigidity, can

meet all kinds of machine stroke and various types parts of

high-precision processing, strong and perfect suction, the maximum

magnetic force up to 16kgf/cm2.

Compared with the traditional clamp, the permanent magnet chuck

eliminates the need of screw, platen and other fixture, the work

piece is easy to install, to achieve a clamping 5-sided

processing,rapid batch processing improve production efficiency.

With the use of elastic magnetic block,deformation of the work

piece can easily grasp the processing, and the adsorption force is

uniform, will not make the work piece stress deformation.

Magnetic Chuck Technical Parameter

| Numbers | Model | Width

(mm) | Length (mm) | Height

(mm) | Pole size (mm) | Pole number (pcs) | Weight (kg) |

| 1 | QEPM 50-2434 | 240 | 340 | 58 | 50 | 12 | 40 |

| 2 | QEPM50-2449 | 240 | 490 | 58 | 50 | 18 | 50 |

| 3 | QEPM 50-2464 | 240 | 640 | 58 | 50 | 24 | 70 |

| 4 | QEPM 50-2479 | 240 | 790 | 58 | 50 | 30 | 90 |

| 5 | QEPM 50-2494 | 240 | 940 | 68 | 50 | 36 | 120 |

| 6 | QEPM50-24109 | 240 | 1090 | 68 | 50 | 42 | 140 |

| 7 | QEPM 50-3034 | 300 | 340 | 58 | 50 | 16 | 50 |

| 8 | QEPM 50-3049 | 300 | 490 | 58 | 50 | 24 | 70 |

| 9 | QEPM 50-3064 | 300 | 640 | 58 | 50 | 32 | 90 |

| 10 | QEPM 50-3079 | 300 | 790 | 58 | 50 | 40 | 110 |

| 11 | QEPM 50-3094 | 300 | 940 | 68 | 50 | 48 | 150 |

| 12 | QEPM50-30109 | 300 | 1090 | 68 | 50 | 56 | 1/0 |

| 13 | QEPM 50-3634 | 360 | 340 | 58 | 50 | 20 | 60 |

| 14 | QEPM 50-3649 | 360 | 490 | 58 | 50 | 30 | 80 |

| 15 | QEPM 50-3664 | 360 | 640 | 58 | 50 | 40 | 110 |

| 16 | QEPM50-3679 | 360 | 790 | 58 | 50 | 50 | 130 |

| 17 | QEPM 50-3694 | 360 | 940 | 68 | 50 | 60 | 170 |

| 18 | QEPM50-36109 | 360 | 1090 | 68 | 50 | 70 | 200 |

| 19 | QEPM 50-4234 | 420 | 340 | 58 | 50 | 24 | 70 |

| 20 | QEPM 50-4249 | 420 | 490 | 58 | 50 | 36 | 95 |

| 21 | QEPM 50-4264 | 420 | 640 | 58 | 50 | 48 | 120 |

| 22 | QEPM50-4279 | 420 | 790 | 58 | 50 | 60 | 150 |

| 23 | QEPM 50-4294 | 420 | 940 | 68 | 50 | 72 | 200 |

| 24 | QEPM50-42109 | 420 | 1090 | 68 | 50 | 84 | 230 |

| 25 | QEPM 50-4834 | 480 | 340 | 58 | 50 | 28 | 80 |

| 26 | QEPM 50-4849 | 480 | 490 | 58 | 50 | 42 | 90 |

| 27 | QEPM 50-4864 | 480 | 640 | 58 | 50 | 56 | 120 |

| 28 | QEPM 50-4879 | 480 | 790 | 58 | 50 | 70 | 1O |

| 29 | QEPM 50-4894 | 480 | 940 | 68 | 50 | 84 | 170 |

| 30 | QEPM50-48109 | 480 | 1090 | 68 | 50 | 98 | 190 |

Advantages of Magnetic Chuck

1. Strong magnetic force, high precision machining

Table maximum suction 13-16kg / cm ², is about 2 times the ordinary

magnetic sucker to ensure that the workpiece fixture will not be a

clear shift, due to the processing process does not require power

supply, so this product does not exist thermal deformation,

effectively guarantee The processing accuracy.

2. Strong security, energy saving and environmental protection

Machining center sucker in the course of the work does not require

electricity, rely on permanent magnet suction suction work-pieces,

to avoid the electromagnetic system in the sudden power failure and

damage to the magnetic loss of the work-piece and the risk of

falling off the work-piece. As the permanent magnet sucker only in

the magnetization and demagnetization process within 1-2 seconds of

the use of electricity, work without the use of any energy and

produce safe, strong and efficient force, both economic and

environmentally friendly.

This new type of CNC machining center disk in the instant power

after the permanent magnet can be hardened work-piece positioning

processing, the application of reverse current, you can demolish

the work-piece removed, safe and energy saving, easy to operate, no

temperature rise and change, processing accuracy high.

Strong support. In theory, the unit of permanent magnet fixture

clamping force of 150 KN, far greater than the cutting force, even

the uneven surface of the fur, but also safe to suck, even if the

milling quality of 52 HRC hardened hardened work-piece, the same

can normal work.

3. Save cost,no maintenance cost.

Magnetic flux leakage phenomenon. Electromagnetic permanent magnet

fixture in the suction clamping process, but there is magnetic

force on the surface of the fixture, the other surface does not

exist magnetic flux leakage phenomenon, not only the tool without

any effect, and remove the work-piece, the fixture and the

work-piece will not exist maintenance , Because the system has an

internal electro mechanical demagnetization device, the work-piece

and fixture can be automatically demagnetized.

4. Easy to use.

The advantage of the permanent magnet fixture is that the

work-piece positioning and clamping is very convenient, do not need

cumbersome and strenuous manpower operation. At the same time,

because the suction force is only in the bottom of the work-piece,

the work-piece does not need to use the clamping plate clamping, to

avoid the clamping force caused by the work-piece deformation and

scratches. The permanent magnet fixture can realize the automatic

adjustment of the work-piece. At the same time, it can realize the

machine tool without vibration cutting, grinding, milling and so

on, which can prolong the service life of the machine.

Application cases